Just found an old @Rapidonline 1999 catalogue, wonder if any part numbers are still valid! #nostalgia pic.twitter.com/aGm2lHk3

— OpenEnergyMonitor (@Openenergymon) February 12, 2013

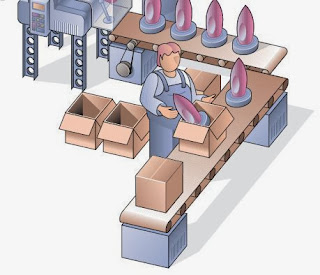

Our customers like to order like its 1999.

@Rapidonline ok...thats a bit freaky...I ordered this at about 7pm LAST NIGHT...telepathy orders next?! pic.twitter.com/wjHy88DfX9

— concrete dog (@concreted0g) March 28, 2013

Obviously we take great pride in our delivery times, but even we seemed to have surpassed ourselves in receiving, picking and despatching an order from Colchester to deepest North Wales in around 15 hours. All this at a time when much of the country was blanketed in snow. Go us!

@sconemad All part of being electronics & education specialists! We also do handles & candles, folders & solder, wallets & grommets

— Rapid Electronics (@Rapidonline) June 19, 2013

I like to think of the above as our alternative corporate biography.

@Rapidonline We should be landing near Basingstoke

— Project Horizon (@horizonqmgs) July 6, 2013

We were delighted to sponsor and follow the progress of a Walsall school's weather balloon project. The unseasonable wintry weather (see above) put paid to their planned Spring launch, but they could not have picked a more glorious day to finally make their ascent in the summer. It was exciting to plot the balloon's journey via tweets and a GPS tracking service on the day, and even better when we saw the incredible footage the camera took 20 miles above the Earth. Queen Mary's Grammar School are now planning to go even higher in 2014 with their 'Beat Felix' (Baumgartner, who skydived from 24 miles up) project.

My dad just gave me some old school full fat tin/lead solder! http://t.co/2ZMSH6yQQ4

— Spaceship Mark (@spaceshipmark) July 9, 2013

Thankfully solder doesn't seem to have a sell-by date!

.@Rapidonline Superb mobile site, works great on Windows Phone as well as the more common mobiles. http://t.co/vNZyI4r41I

— Peak Electronic Des. (@peakatlas) October 11, 2013

In October we launched our mobile website, putting an end to all that tapping and enlarging ...

@Rapidonline got mine :) #excited pic.twitter.com/WzWPIQ2kRo

— samanthazoek (@samanthazoek) November 8, 2013

The first photo taken with our #BigShot camera from @Rapidonline pic.twitter.com/wE4sD3ri54

— Chris Leach (@chrisleach78) November 29, 2013

In late summer we stumbled across news of the Bigshot - the world's first DIY digital camera. It had been developed specifically for education, giving children an insight into how the electronics of photography works. We loved the concept, and were delighted to become the first (and at present only) UK distributor of the product. A lovely review by Rachel Riley on The Gadget Show helped the Bigshot buzz, and there will be plenty of cameras under Christmas trees in a few days time.

Possibly my favorite Christmas catalogue. @Rapidonline pic.twitter.com/BRvwWd8ClF

— Christopher Hardie (@Chimbles84) December 12, 2013

It seems Argos have a rival for their "laminated book of dreams". What does 2014 have in store? Follow us on Twitter to find out (but then you probably do already ...)